Grupo Industrial C&C

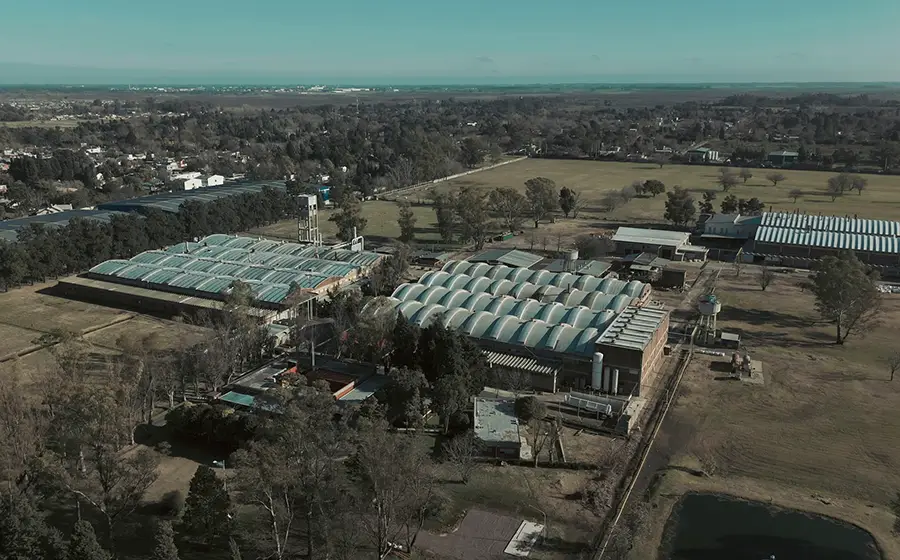

Grupo Industrial C&C is comprised by the following companies: Calles y Chernitsky S.A. founded in 1922, Sotyl S.A. founded in 1943 and Oxido Metal S.A. founded in 1985. Its 70 acres’ industrial facilities are located in Pilar, in the province of Buenos Aires, with a covered surface of 6 acres.

Sotyl S.A.

Sotyl S.A. is leader in copper -and its alloys- casting and rolling; besides, it is the main local manufacturer of straps made of phosphorous bronze, alpaca and special alloys. Besides, it is the most important exporter in this product category.

Oxido Metal S.A.

Oxido Metal S.A. is one of the companies that comprise Grupo Industrial C&C. It is leader in the domestic market of alloys of non ferrous metals, zinc oxide, zinc-base alloys and antimony trioxide, for a broad variety of applications.

Founded by Calles and Chernitsky in 1922.

A business group with Argentine capital and over 100 years of experience.

In the non-ferrous metals industry, we supply raw materials to companies in various sectors.

We operate in our own 280,000-acre industrial park located in Pilar, 50 km from the City of Buenos Aires, with a covered area of 27,000 m².

Years of Experience

Years

Sotyl

Tons per Year

(Copper-base Rolled Products)

Oxido Metal

Tons per Year

(Zinc- and Aluminium-base Alloys)

Active Clients

Covered Area

m2